EDOS Series

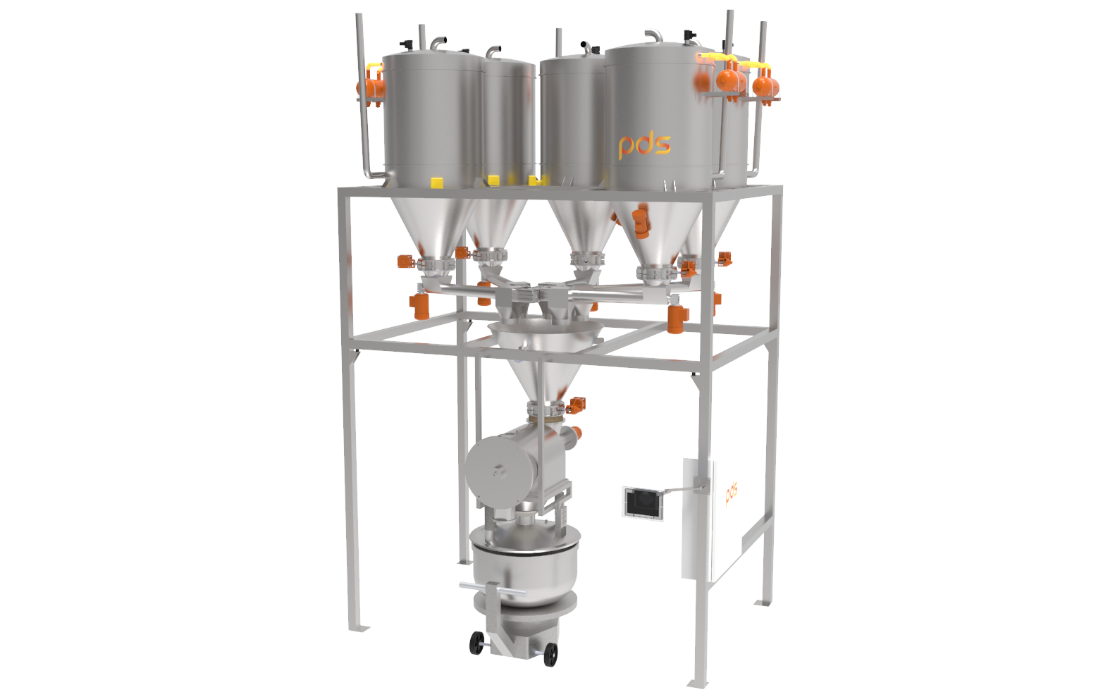

A modular and enlargeable module to automatically dose majority products. This equipment enables the creation of precision recipes and high productivity due to its design and reloading system.

Technical Specification

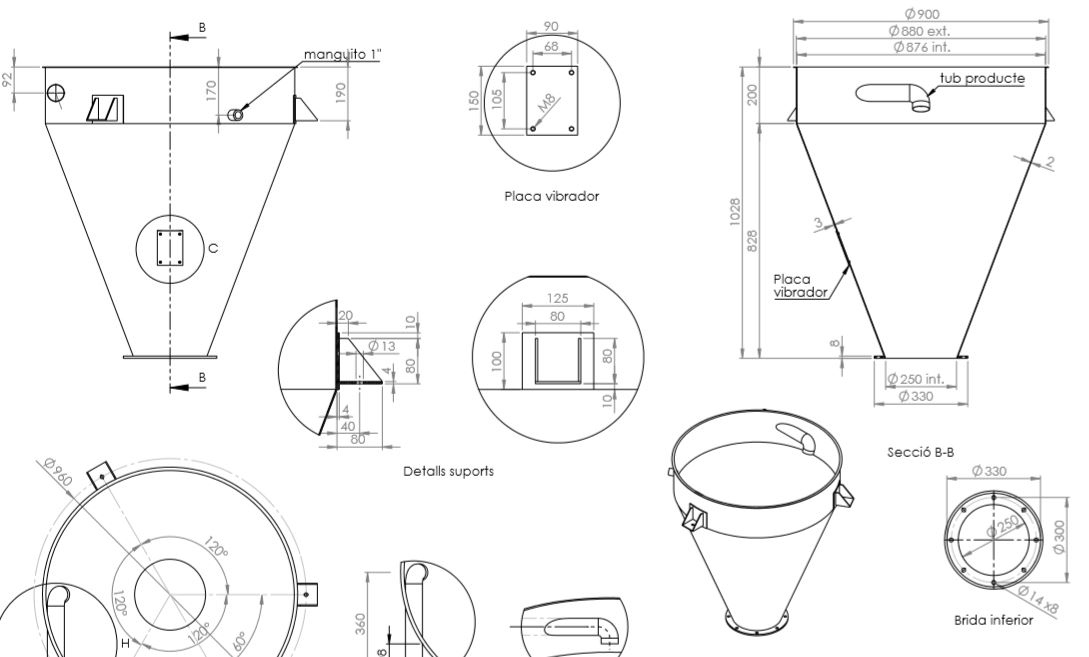

Dimensions of the installation

- L: 2.000 mm

- W: 2.000 mm

- H: 4.000 mm

Capacity of the hoppers

15L-100L depending on the quantity to be dosed

Weighing capacity

100 kg

Productivity

1.500 kg/h

Power consumption

7 kW

1. Increased productivity

The system reloads the hoppers at the same time as the recipe is dosed, eliminating waiting times between dosages and therefore increases the productivity of the production process.

2. Modular design

The POWDER DS EDOS dosing equipment can incorporate as many storage hoppers as the client needs, therefore, it can be programmed to carry out dosing of different recipes with diverse ingredients.

3. Improved quality

EDOS equipment improves the quality of the final product, as the dosing process, designed according to the ingredient to be dosed, offers great precision. It also has a sifting system, adapted to the client’s needs and ensuring a high quality final product.

4. Recipe automotion

The EDOS POWDER DOSING SYSTEM dosing equipment has an HMI viewing and control system that offers two significant advantages; it enables up to 999 different recipes to be stored, which are easily selectable via a touchscreen. It allows recipe repetition cycles to be programmed, freeing personnel from the tasks of managing and controlling the dosage and formulation process. It also has a system with several levels of passwords to avoid unauthorised access to the formulation.

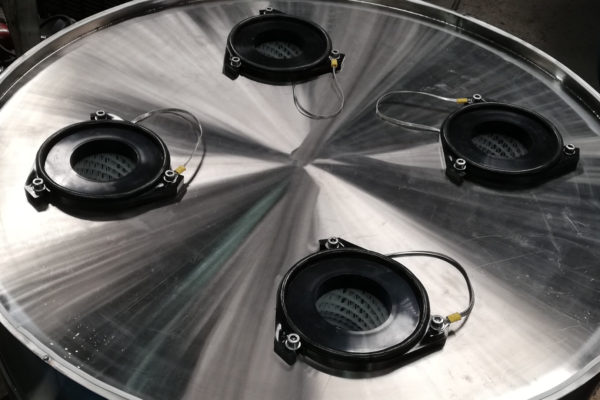

5. Cleaning system

As it is a modular station, the components can easily be dismantled for faster manual cleaning. The filter system is cleaned automatically, without interfering with the production process, increasing the efficiency of the installation.

Added value

Operation

The EDOS POWDER DS dosing equipment is designed to increase clients’ profits. Automation of the dosing process means freeing your personnel from a repetitive task and responsibility, guaranteeing the exact proportions of each recipe.

In addition, the EDOS station significantly increases the productivity of the recipe preparation process for two reasons: Firstly, because while you are dosing the different ingredients in the hoppers, the system reloads them, to be able to start the dosing process immediately. Secondly, because while the operator is removing the bowl with the formulation made, the next recipe is automatically being prepared, avoiding downtime between processes.

Multimedia

More productimages and videos.

Request more information

Contact us

For further information, please contact us using the following contact form, and we will reply as soon as possible.

- Purpose: To respond to your request and send you commercial information on our products and services.

Legitimation: Consent of the person concerned. - Adresses: No transfer of data is foreseen.

- Rights: Access, rectification, suppression, opposition, limitation of treatment, portability in contact with us by sending an e-mail to info@powderds.com.

- Additional information: For further information, please click on the link to the Privacy Policy