TPF Series

Automation of dosing processes in the bakery, confectionery or pasta industries means increasing productivity and improving the quality of the final product.

Technical Specifications

Dimensions of the installation

- L: 1.000 mm

- W: 1.000 mm

- H: 3.500 mm

Productivity

1000 kg/h

Weighting capaciity

250 kg

Capacity of the hopper

50-200L depending on the quantity to be dosed

Power consumption

3 kW

1. Increased efficiency

The use of automated conveying and dosing systems avoids repetitive work with little added value, enabling workers to focus on other tasks in the production process.

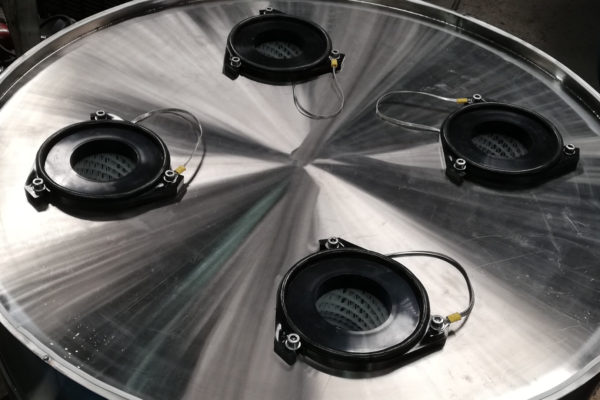

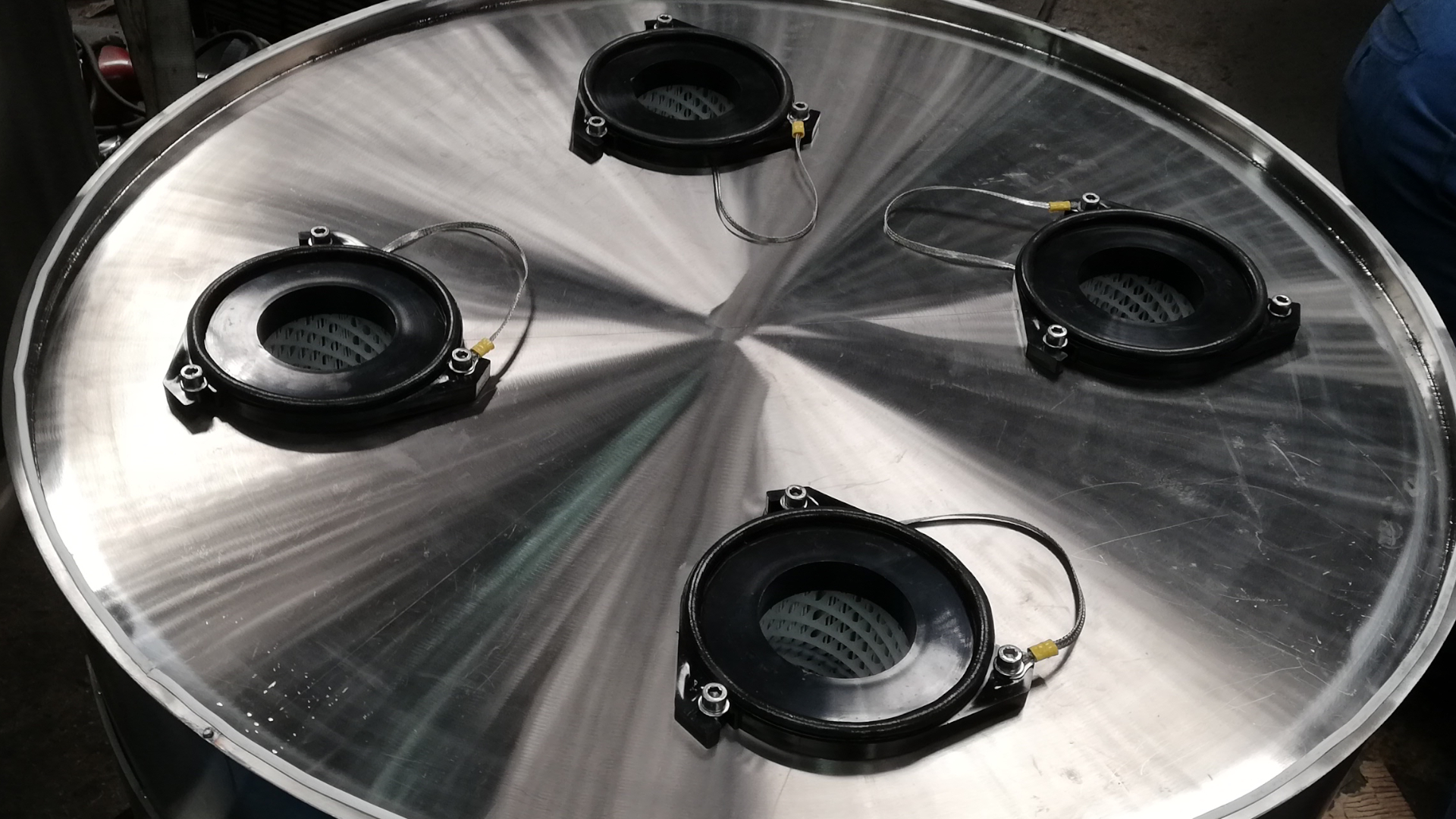

2. Cleaning system

The TPF transport and dosing system is easily dismantled to replace the filter, while at the same time incorporating an automated cleaning system based on blowing.

3. Improvements in quality

The high precision of the POWDER DS TPF dosing system enables final product quality to be improved and optimises raw material consumption costs.

4. Recipes automation

Automation of dosing and recipes preparation processes avoids errors, increases the precision of the recipes and increases productivity and the quality of the final product.

Added value

Operation

The POWDER DOSING SYSTEMS TPF conveying and dosing system can be used to convey any type of solid from silos or bulk bag dischargers to a dosing hopper. By means of a pneumatic conveying system and a filter, the TPF system loads the ingredients into a hopper for dosing according to the recipe or formula recorded in the control and management system.

All POWDER DS equipment is manufactured with top quality materials and components, certified for food processing (AISI 304 and 316 stainless steel) and the control and management components are made by leading brands.

Multimedia

More product images and videos.

Request more information

Contact us

For further information, please contact us using the following contact form, and we will reply as soon as possible.

- Purpose: To respond to your request and send you commercial information on our products and services.

Legitimation: Consent of the person concerned. - Adresses: No transfer of data is foreseen.

- Rights: Access, rectification, suppression, opposition, limitation of treatment, portability in contact with us by sending an e-mail to info@powderds.com.

- Additional information: For further information, please click on the link to the Privacy Policy